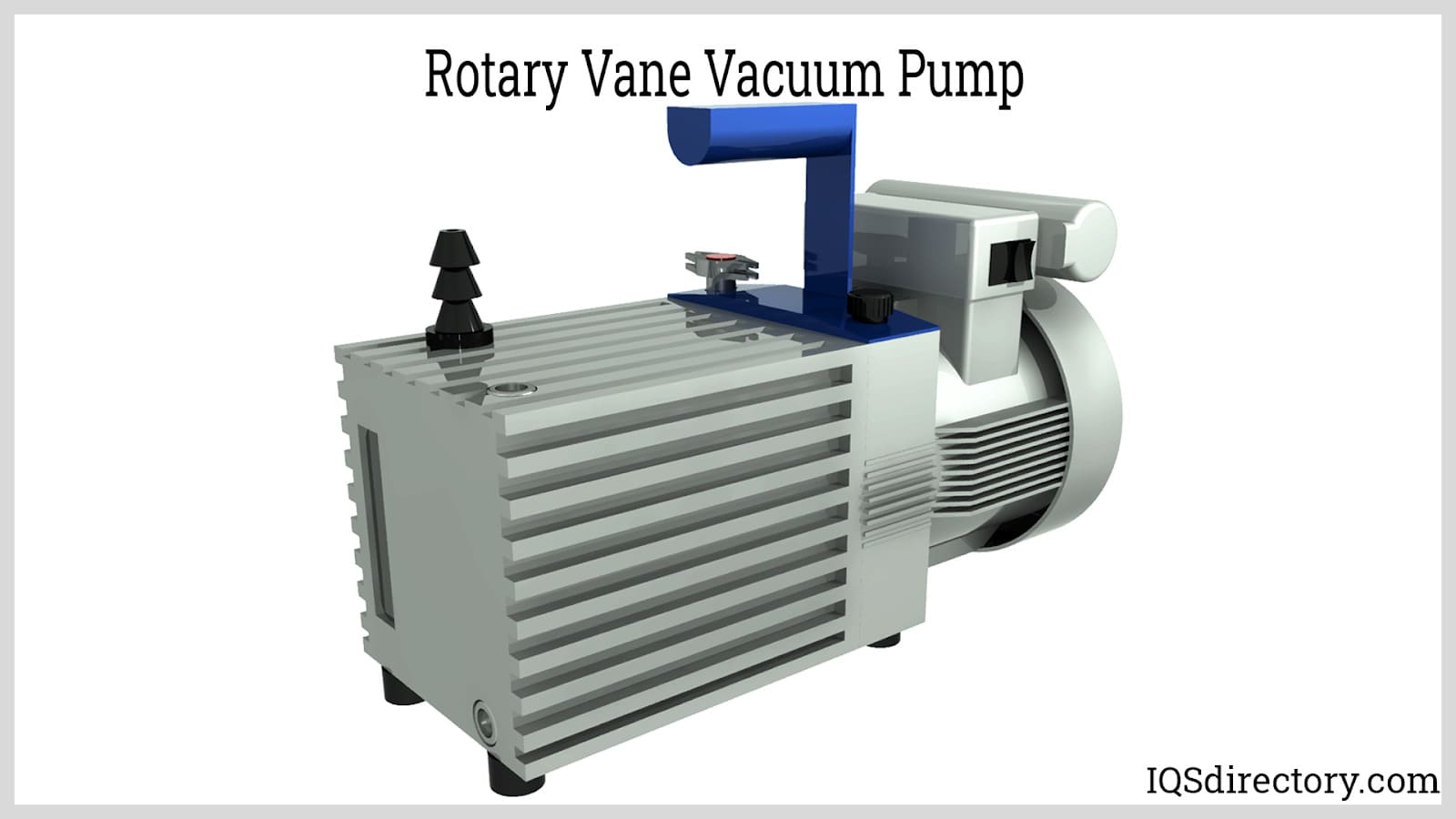

In its most basic form, a rotary vane vacuum pump is a pump technology that allows air to be compressed inside the pump chamber to create suction. This suction removes air molecules from a vessel or area. Rotary vane vacuum pumps operate based on the positive displacement pumping theory. They are designed with a rotor positioned inside a cylindrical housing or stator. Due to centrifugal force, blades positioned inside the rotor rotate in and out while adhering to the interior surface of the housing. Read More…

Busch Vacuum Solutions is a leading manufacturer of vacuum pumps, blowers, compressors, and customized systems using vacuum technology. With over 60 years of experience, Busch offers the largest selection of industrial vacuum and pressure technology available today to meet their customer’s operating and cost saving goals. Contact us today!

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

Gast Manufacturing specializes in rotary vane, oilless, miniature, high-volume and dry vacuum pump products. We provide efficient, reliable vacuum pumps for a variety of applications. Our commitment to quality products, great service and environmentally friendly practices is unparralled.

At KNF Neuberger Inc., we specialize in providing high-performance vacuum pumps tailored to meet the demanding needs of diverse industries. Our vacuum pumps are designed with precision and reliability, offering optimal solutions for applications ranging from laboratory and medical environments to industrial and processing fields.

At Vacuubrand, we specialize in providing advanced vacuum technology solutions tailored for laboratory and industrial applications. We manufacture a comprehensive range of vacuum pumps, including oil-free diaphragm pumps, rotary vane pumps, and hybrid systems, all engineered for reliability, chemical resistance, and low maintenance.

Airtech is a leading manufacturer/supplier of various types of quality dry piston vacuum pressure pumps, rotary vane pumps (lubricated, dry), liquid ring vacuum pumps. We possess vast knowledge as a vacuum specialist. Serving medical, dental, food packaging and other industries. US warehousing.

At Welch Vacuum, we specialize in the design and manufacturing of high-quality vacuum pumps tailored to meet the diverse needs of industries worldwide. With a long history of innovation, we deliver reliable and efficient solutions for applications ranging from laboratory research to industrial processes.

More Rotary Vane Vacuum Pump Manufacturers

Design of Rotary Vane Vacuum Pump

Rotary vane vacuum pumps are a fundamental type of positive displacement vacuum pump used extensively across a wide array of industrial and laboratory applications. Their core function is to create a vacuum by continuously evacuating air or gas from an enclosed space, making them essential in processes that require controlled atmospheric conditions. By leveraging positive displacement technology, rotary vane pumps operate by cyclically trapping a fixed volume of gas and moving it from the pump's inlet to its outlet, ensuring reliable vacuum generation without the need for infinite expansion.

There are two main configurations for rotary vane vacuum pumps: oil-sealed (wet) and dry-running (oil-free). Oil-sealed rotary vane pumps utilize a specially formulated vacuum pump oil to create a tight seal, enhance performance, and reduce wear, making them ideal for high-vacuum and heavy-duty operations. Alternatively, dry rotary vane pumps forego lubrication, instead relying on precision engineering and tight mechanical tolerances for efficient, contaminant-free vacuum generation. This distinction is critical for buyers evaluating pump types for sensitive environments such as cleanrooms or pharmaceutical manufacturing, where oil contamination must be avoided.

Understanding the main components of rotary vane vacuum pumps is crucial when selecting the right pump for your application. While the specific design, size, or model can introduce some variation, the following core parts are typical of most oil-lubricated and dry-running rotary vane pumps:

- Rotor: The rotor is a cylindrical component—often copper-wound for efficient conductivity—that rotates within the pump housing. Driven by the motor, it provides the motion necessary to drive the vanes and facilitate continuous vacuum generation.

- Stator: Surrounding the rotor, the stator serves as the stationary component of the electric motor, providing the magnetic field required for rotor movement. The interplay between the stator and rotor is fundamental to the pump's energy efficiency and reliability.

- Vanes or Blades: The vanes are durable, sliding blades set into slots of the rotor. As the rotor spins, centrifugal force pushes the vanes outward against the walls of the pump chamber, forming airtight seals that move and compress the gas. High-wear vanes are often constructed from advanced composites or carbon to extend service life and reduce maintenance intervals.

- Oil Sump (in oil-lubricated models): The oil sump is a reservoir that stores vacuum pump oil used for both sealing and lubrication. An integrated oil pump circulates oil through the system, ensuring moving parts remain protected from friction and heat. The oil also acts as a barrier against gas backflow, maintaining optimal vacuum levels.

- Suction Flange: The suction flange connects the vacuum pump to the process system or chamber, forming a leak-proof interface that prevents fluid or gas ingress. Proper flange selection is vital for system integrity and reliable operation.

- Cylindrical Housing: Enclosing the internal mechanism, the housing (often made from robust aluminum die-casting) provides structural integrity and dissipates heat generated during operation. The compact, rugged design of the housing is key for demanding industrial settings.

- Motor: The electric motor (available in AC or DC versions) transforms electrical energy into mechanical energy, providing the torque needed for rotor rotation and efficient pump operation. Energy efficiency and power rating are key considerations for buyers evaluating different pump models.

- Float Valve: Integrated into oil-lubricated pumps, the float valve automatically regulates oil flow in response to elevation changes, preventing oil loss and ensuring consistent sealing performance.

Each of these components plays a crucial role in the performance, efficiency, and longevity of rotary vane vacuum pumps. When considering purchasing a rotary vane vacuum pump, it is important to evaluate the quality and design of these components, as well as the compatibility of the pump with your intended application. Are you comparing oil-sealed versus dry rotary vane pumps? Evaluate the maintenance requirements, operational costs, and contamination risk for each type to make an informed decision.

Applications of Rotary Vane Vacuum Pumps

Rotary vane vacuum pumps are versatile, reliable, and widely adopted across numerous industries because of their robust performance, ease of maintenance, and adaptability to both low and high vacuum applications. Their ability to deliver consistent vacuum levels, even under variable process conditions, makes them a preferred choice for manufacturers, laboratories, and technical service providers. Below, we explore both oil-lubricated and dry-running rotary vane vacuum pump applications in greater detail:

Oil-Lubricated Rotary Vane Vacuum Pump Applications

- Chemical and Pharmaceutical Processing: Essential for degassing, crystallization, solvent recovery, vacuum distillation, evaporation, drying, supercooling, fractionation, impregnation, and vacuum filtration. The high reliability and deep ultimate vacuum levels delivered by oil-lubricated rotary vane pumps make them indispensable for research labs, pilot plants, and production lines.

- Food and Beverage Packaging: Utilized in bottling, vacuum packing, and filling machinery, rotary vane pumps help preserve freshness and extend shelf life by removing air and inhibiting oxidation or microbial growth. Centralized vacuum systems equipped with these pumps support high-speed production lines and automated packaging cells.

- Industrial Manufacturing: Deployed in vacuum hold-down systems for CNC machining, dust extraction equipment, drying ovens, autoclaves, and industrial furnaces. Their ability to handle continuous operation and tolerate process contaminants ensures reliable uptime in demanding environments.

- Pneumatic Conveying: Used to transport powders, granulates, and bulk solids in industries such as plastics, pharmaceuticals, and food processing. Rotary vane pumps provide the stable vacuum required for material movement and separation.

- Medical and Laboratory Equipment: Found in vacuum ovens, aspiration systems, and sample preparation devices, oil-lubricated rotary vane pumps deliver the precise vacuum control and stability needed for sensitive analyses and procedures.

- HVAC and Refrigeration: Used in air conditioning and refrigeration unit evacuation, leak checking, and system dehydration. The robust design of oil-lubricated pumps ensures repeatable performance across numerous service cycles.

Dry Running Rotary Vane Vacuum Pump Applications

- Environmental Engineering: Critical for soil remediation, groundwater treatment, and aeration processes. Dry running rotary vane pumps ensure oil-free operation, preventing hazardous contamination in eco-sensitive environments.

- Industrial Automation: Employed for picking and placing, lifting and holding, and robotic end-effectors. The clean, maintenance-friendly design of dry-running pumps makes them ideal for integration into automated production lines and robotics.

- Packaging and Printing: Used in post-press equipment, printing presses, and vacuum packaging machinery, dry rotary vane pumps support high throughput rates while eliminating oil-related maintenance and emissions.

- Woodworking Industry: Provide vacuum hold-down capability for CNC routers, laminating, and veneering machines, helping to ensure workpiece stability and accuracy during machining operations.

- Electronics Manufacturing: Applied in PCB handling, component placement, and semiconductor processing, where oil-free vacuum is necessary to prevent contamination and meet stringent quality standards.

- Medical Technology: Utilized in sterilization, aspiration, and suction devices, dry rotary vane pumps deliver hygienic, oil-free performance compliant with medical regulations.

How Do You Choose the Right Rotary Vane Vacuum Pump for Your Application?

When selecting a rotary vane vacuum pump, it is important to consider factors such as the required vacuum level, pumping speed, compatibility with process gases, environmental restrictions, and maintenance preferences. Ask yourself:

- What is the ultimate pressure or vacuum level needed for your process?

- Is oil contamination a concern in your application, or can you leverage the superior vacuum performance of oil-sealed pumps?

- Do you require continuous duty operation, or will the pump be used intermittently?

- Are there specific certification or compliance requirements (such as ISO, CE, or RoHS) for your industry?

- What is your available budget for capital expenditure and ongoing maintenance?

- Do you need integrated control systems, variable speed drives, or remote monitoring capabilities?

Answering these questions will help you narrow down your options and select a vacuum pump that delivers the best balance of performance, reliability, and total cost of ownership.

Advantages and Benefits of Rotary Vane Vacuum Pumps

Rotary vane vacuum pumps are among the most popular and widely used vacuum pump technologies available today. Their robust design, energy efficiency, and adaptability to diverse applications have made them the industry standard for both general-purpose and specialized vacuum needs. Discover the primary benefits that set rotary vane pumps apart:

- High Efficiency and Performance: Rotary vane pumps deliver rapid evacuation times, excellent ultimate vacuum levels, and stable performance even under fluctuating loads. They are capable of handling both low and medium vacuum ranges with ease.

- Versatility: Suitable for a wide range of gases and vapors, they can be adapted for use in chemical, biological, food, and industrial settings. Specialized variants can handle corrosive gases or integrate with solvent recovery systems.

- Reliability and Durability: Engineered for continuous operation, rotary vane pumps are built to withstand demanding process environments with minimal downtime. Their simple mechanical design translates to fewer failures and reduced risk of process interruption.

- Cost-Effective Operation: Low initial investment costs, straightforward maintenance, and long service intervals make rotary vane vacuum pumps an economical choice for facilities seeking to optimize total cost of ownership.

- Compact Footprint: Space-saving designs allow easy integration into existing systems or mobile applications, making them ideal for laboratory benches, OEM equipment, and skid-mounted industrial solutions.

- Low Noise and Vibration: Modern rotary vane pumps feature advanced balancing and damping technologies for quiet, smooth operation, contributing to safer and more comfortable work environments.

- Scalability: Available in a wide range of sizes and flow rates, rotary vane pumps can serve both small-scale laboratory setups and large-scale industrial processes.

- Ease of Maintenance and Service: User-friendly access to service points, readily available spare parts, and clear maintenance guidelines reduce labor costs and maximize pump uptime.

Common Questions About Rotary Vane Vacuum Pumps

- What is the difference between single-stage and two-stage rotary vane vacuum pumps? Single-stage pumps are suited for most general vacuum applications, while two-stage pumps deliver deeper ultimate vacuums, making them ideal for high-vacuum or scientific research applications.

- Can rotary vane vacuum pumps handle corrosive or reactive gases? Standard models are best suited for air and inert gases. For corrosive or reactive gases, choose pumps with chemically resistant materials and compatible fluids or consider alternative vacuum pump technologies.

- How often should rotary vane vacuum pumps be serviced? Service intervals depend on the application, duty cycle, and environmental conditions. Routine checks on oil level and quality (for oil-sealed pumps), vane wear, and filter cleanliness are recommended. Refer to manufacturer guidelines for specific maintenance schedules.

- Are rotary vane pumps energy efficient? Yes, especially modern models featuring variable frequency drives and smart controls, which optimize energy consumption based on demand and minimize operational costs.

- Where can I find replacement parts and technical support? Most reputable rotary vane vacuum pump suppliers offer comprehensive support, including spare parts, technical documentation, and field service.

Choosing the Right Rotary Vane Vacuum Pump Supplier

The selection of a reliable rotary vane vacuum pump supplier is a crucial step when investing in new vacuum technology. A knowledgeable supplier can provide expert guidance on product selection, installation, and after-sales support, helping you maximize the value of your investment. Here are some key considerations to guide your supplier evaluation process:

- Experience and Expertise: Does the supplier have a proven track record in your industry? Look for suppliers with expertise in your application area, whether it's chemical processing, food packaging, laboratory research, or manufacturing automation.

- Product Range and Customization: Does the supplier offer a comprehensive portfolio of rotary vane vacuum pumps, including both oil-sealed and dry-running models? Can they customize pumps to meet unique process requirements such as special voltages, explosion-proof ratings, or integrated controls?

- Quality Certifications: Ensure the supplier complies with relevant international standards such as ISO 9001, CE, or industry-specific certifications. This guarantees product quality, safety, and regulatory compliance.

- Technical Support and Service: Look for suppliers who provide detailed documentation, installation support, preventive maintenance programs, and rapid-response field service to minimize downtime and maximize operational efficiency.

- Delivery and Lead Times: Assess the supplier’s ability to meet your delivery schedules and respond to urgent requirements. Reliable logistics and inventory management are critical for seamless project execution.

- References and Reviews: Ask for customer references and review case studies or testimonials to gauge supplier reliability and satisfaction levels among previous clients.

- Aftermarket Support: Consider suppliers who offer comprehensive aftermarket services, including spare parts, repairs, performance upgrades, and retrofit solutions.

To ensure a successful procurement process when purchasing a rotary vane vacuum pump, compare at least four suppliers using our rotary vane vacuum pump directory. Each supplier’s profile highlights areas of experience, technical capabilities, and product offerings. Use our website previewer to conveniently review each company’s specialties, and leverage our simple RFQ (Request for Quote) form to contact multiple suppliers at once with your project requirements. This streamlined approach ensures you receive the most competitive pricing, delivery terms, and technical advice tailored to your application.

Ready to Request a Quote or Need More Guidance?

If you’re ready to find the best rotary vane vacuum pump for your specific application, visit our rotary vane vacuum pump supplier directory to get started. Need help understanding pump sizing, performance data, or installation requirements? Reach out to our technical experts for personalized assistance and recommendations based on your unique needs.

Rotary Vane Vacuum Pump Resources and Further Reading

- Comprehensive Vacuum Pump Manufacturer Directory

- Learn More About Rotary Vane Vacuum Pump Technology

- Industry-Specific Vacuum Pump Applications

- Contact Technical Support

Explore our additional resources or contact us for expert advice on selecting, installing, and maintaining your rotary vane vacuum pump. Whether you’re upgrading existing equipment, specifying new projects, or troubleshooting vacuum system issues, our team is here to support your success every step of the way.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services