An industrial vacuum pump is a mechanical tool used to remove gases or liquids from the inside of tubes, containers, or any other system when it is necessary to lower the internal pressure below atmospheric levels. Systems for industrial vacuum pumps are created for usage in several sectors, including the manufacturing, semiconductor, and food and beverage sectors. These systems are often made to last and see heavy industrial use. Read More…

Busch Vacuum Solutions is a leading manufacturer of vacuum pumps, blowers, compressors, and customized systems using vacuum technology. With over 60 years of experience, Busch offers the largest selection of industrial vacuum and pressure technology available today to meet their customer’s operating and cost saving goals. Contact us today!

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

Gast Manufacturing specializes in rotary vane, oilless, miniature, high-volume and dry vacuum pump products. We provide efficient, reliable vacuum pumps for a variety of applications. Our commitment to quality products, great service and environmentally friendly practices is unparralled.

At KNF Neuberger Inc., we specialize in providing high-performance vacuum pumps tailored to meet the demanding needs of diverse industries. Our vacuum pumps are designed with precision and reliability, offering optimal solutions for applications ranging from laboratory and medical environments to industrial and processing fields.

At Vacuubrand, we specialize in providing advanced vacuum technology solutions tailored for laboratory and industrial applications. We manufacture a comprehensive range of vacuum pumps, including oil-free diaphragm pumps, rotary vane pumps, and hybrid systems, all engineered for reliability, chemical resistance, and low maintenance.

Airtech is a leading manufacturer/supplier of various types of quality dry piston vacuum pressure pumps, rotary vane pumps (lubricated, dry), liquid ring vacuum pumps. We possess vast knowledge as a vacuum specialist. Serving medical, dental, food packaging and other industries. US warehousing.

At Welch Vacuum, we specialize in the design and manufacturing of high-quality vacuum pumps tailored to meet the diverse needs of industries worldwide. With a long history of innovation, we deliver reliable and efficient solutions for applications ranging from laboratory research to industrial processes.

More Industrial Vacuum Pump Manufacturers

Industrial Vacuum Pump’s Operating Principle

Industrial vacuum pumps are essential components in a wide range of manufacturing and processing industries. Regardless of the underlying technology, the fundamental operating principle of an industrial vacuum pump is the removal of air molecules and other gases from a designated vacuum chamber or system. By continuously extracting air, these pumps create a pressure differential, effectively reducing the chamber pressure and enabling a vacuum environment necessary for various industrial applications.

As the vacuum level increases and the chamber's pressure drops, it becomes progressively more difficult to remove additional gas molecules. This operational challenge is why a typical industrial vacuum system often incorporates several types of pumps working in series or parallel, each optimized for a particular segment of the pressure range. For example, industrial vacuum systems may operate from atmospheric pressure (1 Torr) down to ultra-high vacuum levels as low as 10-9 Torr, as commonly required in advanced research and scientific fields.

In many industrial settings, achieving and maintaining a specific vacuum level is critical for product quality, process efficiency, and safety. As you explore different vacuum pump technologies, consider the pressure range, pumping speed, and compatibility with process gases as key decision factors. Looking for the right vacuum pump for your application? Read on for a detailed overview of the main types, their uses, and performance characteristics.

Industrial Vacuum Pump Types

Industrial vacuum pumps are categorized by their operating mechanisms, performance ranges, and suitability for different industrial processes. Below, we examine several of the most commonly used vacuum pump types in modern industry.

Axial-Flow Vacuum Pumps

Axial-flow vacuum pumps, also known as centrifugal pumps, deliver energy to fluids (primarily liquids) by imparting centrifugal force through a rotating impeller. These pumps are ideal for applications requiring the transfer of large volumes of fluids under moderate pressure. Their straightforward construction and high flow rates make them popular in water treatment, chemical processing, and certain vacuum-assisted manufacturing processes.

- Best suited for moderate vacuum levels and high flow requirements

- Widely used in industrial liquid transfer and process vacuum applications

- Simple maintenance and robust design suitable for continuous operation

Curious if an axial-flow or centrifugal vacuum pump is right for your facility? Compare flow rates, energy efficiency, and required vacuum levels before making a selection.

Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps operate by using a rotating ring of liquid (typically water or an oil-based fluid) to form a seal within the compression chamber. Unlike rotary vane pumps, which rely on mechanical vanes, the rotating liquid in these pumps provides a low-friction, low-maintenance sealing mechanism. Only the rotor moves, with shaft seals as the only points of sliding friction, making these pumps durable and reliable for demanding environments.

- Excellent for handling wet or corrosive gases and vapors

- Commonly used in chemical processing, food and beverage, pharmaceuticals, and power generation

- Ideal for applications requiring continuous operation and low maintenance

Learn more about liquid ring vacuum pumps and their industrial applications.

Rotary Claw Vacuum Pumps

Rotary claw vacuum pumps are engineered for contact-free, oil-free vacuum generation. Featuring a pair of intermeshing rotors that rotate in opposite directions without touching each other or the housing, these pumps offer highly efficient and reliable operation. Their static compression principle (internal volume contraction) enables excellent energy efficiency and superior performance compared to other dry-running pumps.

- Oil-free technology: eliminates risk of contamination in sensitive processes

- Ideal for packaging, pneumatic conveying, plastics processing, and medical technology

- Minimal maintenance due to non-contact design

Wondering how rotary claw vacuum pumps compare to rotary vane or screw vacuum pumps? Contact our experts to discuss which technology best fits your industry and process requirements.

Side-Channel Blowers

Side-channel blowers utilize a high-speed impeller mounted directly on the motor shaft to provide contact-free compression of gases. As gas enters the inlet, it is accelerated by the impeller’s rotation and guided through a side channel, where repeated acceleration and redirection increase the pressure before the gas exits through the outlet.

- Efficient for low to moderate vacuum and pressure generation

- Common uses include pneumatic conveying, aeration, and air knife applications

- Low noise and vibration levels, suitable for clean environments

Not sure if a side-channel blower or a traditional vacuum pump is better for your process? Compare performance specs and consult with a vacuum pump specialist to determine the optimal solution for your needs.

Other Industrial Vacuum Pump Technologies

There are many additional industrial vacuum pump types that address specific requirements, including:

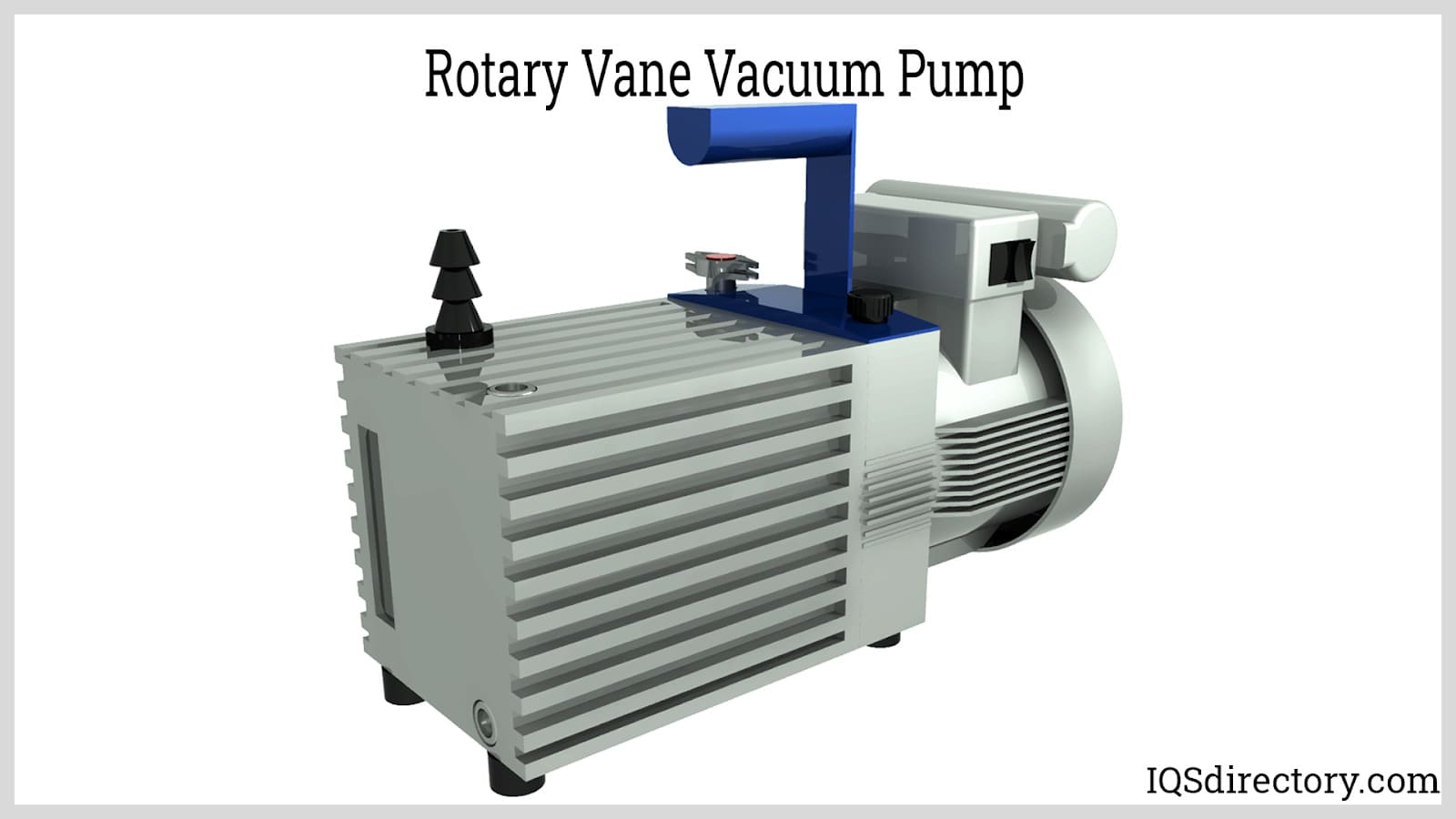

- Rotary vane vacuum pumps: Known for their versatility and strong vacuum performance, widely used in laboratory, refrigeration, and packaging industries.

- Screw vacuum pumps: Ideal for processes requiring dry, oil-free compression and continuous duty cycles, such as semiconductor manufacturing.

- Roots vacuum pumps (blower pumps): Often used as booster pumps in combination with other vacuum technologies to achieve higher pumping speeds at lower pressures.

- Diffusion and turbomolecular pumps: Essential for creating ultra-high vacuum conditions in scientific research and semiconductor fabrication.

Each technology offers unique benefits and trade-offs in terms of initial cost, maintenance requirements, energy efficiency, and suitability for specific gas types. Seeking tailored recommendations? Review our comprehensive vacuum pump selection guide or reach out to an industrial vacuum equipment expert.

Industrial Vacuum Equipment Benefits

Investing in high-quality industrial vacuum equipment delivers a range of operational, financial, and safety advantages. Whether used in manufacturing, materials handling, food processing, or laboratory research, the right vacuum solution can improve productivity, ensure product integrity, and reduce total cost of ownership. Here are some of the most significant benefits:

Capabilities for Customization

Industrial vacuum systems can be customized to meet the unique requirements of each facility or production line. Leading vacuum pump manufacturers and suppliers offer engineering support to design systems that match your process parameters, space constraints, and regulatory requirements. Customization options may include automation integration, remote monitoring, corrosion-resistant materials, and specialized filtration.

- Tailored designs ensure optimal performance for your application

- Scalable systems to accommodate future growth or changes in production

- Integration with existing process control and automation solutions

Looking to customize your industrial vacuum solution? Request a consultation with a vacuum system engineer today.

Longevity and Robustness

Durability and longevity are hallmarks of well-designed industrial vacuum pumps. Constructed from high-strength alloys and engineered for heavy-duty performance, these systems are built to withstand years of demanding service in harsh environments. Regular preventative maintenance and access to OEM parts further extend the useful life of your equipment, minimizing downtime and replacement costs.

- Reduced frequency of replacement and lower lifecycle costs

- Reliability in 24/7 operations and critical process applications

- Warranty and support from reputable vacuum pump suppliers

The Simplicity of Use and Upkeep

Modern industrial vacuum systems are designed for easy operation and minimal maintenance. User-friendly interfaces, remote diagnostics, and clear operating instructions streamline staff training and daily use. Partnering with a top-tier industrial vacuum pump company ensures access to technical support, troubleshooting resources, and fast access to replacement parts.

- Simplified controls and automation minimize operator error

- Low maintenance designs reduce operating expenses

- Comprehensive documentation and customer support available

Wondering how to maintain your industrial vacuum pump for maximum uptime? Explore our vacuum pump maintenance best practices or contact our technical support team.

Process and Product Quality Enhancements

Using the appropriate vacuum system directly impacts product consistency and process efficiency. In sensitive industries such as electronics, pharmaceuticals, and food production, maintaining precise vacuum levels is critical to prevent contamination, ensure purity, and achieve desired product characteristics.

- Consistent vacuum enables repeatable results and tight process control

- Reduces risk of contamination and product defects

- Improves yields and throughput in production environments

Need help ensuring your vacuum system meets quality standards? Contact us for compliance solutions and validation support.

Energy Efficiency and Sustainability

Many modern vacuum pumps are engineered for energy efficiency, incorporating variable speed drives, optimized motor designs, and smart controls. These features help reduce utility costs and minimize environmental impact, supporting sustainable manufacturing practices.

- Lower energy consumption reduces operating expenses

- Eco-friendly options available for green manufacturing initiatives

- Compliance with energy and emissions regulations

Interested in sustainable vacuum solutions? Ask about our energy-efficient vacuum pump models and green retrofit options.

Applications of Industrial Vacuum Pumps

Industrial vacuum pumps are indispensable across a variety of sectors, enabling processes that would be impossible or inefficient without controlled vacuum conditions. Below are some of the most common and critical applications:

The Food Industry

In the food processing sector, vacuum pumps play a key role in applications such as freeze drying (lyophilization), vacuum packaging, degassing, and dehydration. By enabling precise control over atmospheric conditions, these pumps help preserve product quality, extend shelf life, and support safe, hygienic packaging.

- Vacuum packaging for extended freshness and contamination prevention

- Freeze drying to concentrate flavors and preserve nutrients

- Degassing to remove air bubbles from liquids and mixtures

Exploring vacuum pumps for food manufacturing? Review our food industry vacuum pump solutions and compliance certifications.

The Electrical Sector

In the electrical and electronics industries, vacuum systems are essential for drying, impregnation, and encapsulation processes. For example, transformers, capacitors, and coils require vacuum-assisted drying to remove moisture and prevent electrical failure. Additionally, vacuum pumps are used to evacuate air from switchgear and other high-voltage components during manufacturing and maintenance.

- Moisture removal improves dielectric strength and component longevity

- Ensures reliability of critical electrical infrastructure

Curing Resins and Varnishes

Vacuum pumps are widely used in the curing and casting of resins, varnishes, and silicone compounds. By evacuating air and gases before curing, these pumps eliminate bubbles and voids, resulting in stronger, more uniform products. This is especially important in the production of electrical insulators, composite materials, and advanced coatings.

- Improves structural integrity and appearance of finished goods

- Enables high-quality encapsulation and potting processes

Pharmaceutical Companies

In pharmaceutical manufacturing, vacuum technology is critical for drying, filtration, solvent recovery, and packaging. Processes such as freeze drying (lyophilization) and vacuum filtration require precise vacuum control to ensure product stability, efficacy, and sterility. Vacuum packaging is also used to protect sensitive medicines from contamination and degradation during transport.

- Supports compliance with GMP and regulatory standards

- Enables gentle drying and solvent removal without damaging active ingredients

- Facilitates aseptic packaging for extended shelf life

Looking for GMP-compliant vacuum solutions? Browse our pharmaceutical-grade vacuum pump offerings.

The Toy Industry

The toy manufacturing sector utilizes vacuum pumps in coating, molding, and degassing processes. Vacuum-assisted molding ensures precise shapes and surface finishes, while vacuum degassing removes trapped air in plastics and metals, preventing defects and improving product quality.

- Enables intricate designs through vacuum forming and casting

- Improves density and strength of molded components

Optical Technology

In optical manufacturing, vacuum pumps are essential for thin-film deposition, lens coating, and precision glass forming. By creating ultra-clean vacuum environments, these systems support the production of high-performance optical components for cameras, sensors, and scientific instruments.

- Thin film application on lenses, mirrors, and semiconductor wafers

- Production of anti-reflective and protective coatings

Have specialized optical requirements? Contact us to discuss custom vacuum solutions for optics and photonics.

Additional Industrial Applications

Industrial vacuum pumps also support a broad range of other fields, including:

- Semiconductor manufacturing: Ultra-high vacuum pumps for wafer processing and deposition

- Laboratory and research: Controlled environments for analytical instruments, mass spectrometry, and freeze drying

- Automotive: Vacuum-assisted brake systems, fuel system testing, and component drying

- Printing and paper: Vacuum hold-down, paper dewatering, and ink transfer processes

- Environmental engineering: Soil remediation, air sampling, and vapor extraction

Not sure which pump type matches your industry? Use our application guide or reach out for personalized recommendations.

Choosing the Correct Industrial Vacuum Pump Company

Selecting the right industrial vacuum pump supplier or manufacturer is critical to achieving optimum performance and long-term value from your investment. When evaluating potential partners, consider these key factors:

- Industry experience and application expertise: Does the company have a proven track record in your sector?

- Comprehensive product offering: Are a variety of vacuum pump types, sizes, and accessories available?

- Technical support and after-sales service: What is the availability of training, maintenance, and emergency response?

- Customization capabilities: Can the supplier tailor systems to your unique requirements and constraints?

- Certifications and compliance: Are their products certified to meet industry, safety, and environmental standards?

To ensure the most advantageous outcome when purchasing industrial vacuum pumps, use our industrial vacuum pump directory to compare at least four qualified companies. Each profile highlights areas of expertise, manufacturing capabilities, and support offerings. For a streamlined procurement process, use our patented website previewer to evaluate business specialties, then submit a request-for-quote (RFQ) to multiple suppliers with a single form.

Ready to take the next step? Browse our industrial vacuum pump company directory or request a quote today to receive tailored pricing and technical information from leading manufacturers and distributors.

For additional guidance, visit our vacuum pump selection guide or contact our experts for personalized assistance. Empower your operations with the most advanced, reliable, and efficient vacuum technology available on the market.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services