Laboratory vacuum pumps are available in a great variety of technologies in order to satisfy specific laboratory applications. Dry (oil-free) diaphragm pumps can reach down to about 1 Torr and can be designed for exceptional chemical resistance. Read More…

Busch Vacuum Solutions is a leading manufacturer of vacuum pumps, blowers, compressors, and customized systems using vacuum technology. With over 60 years of experience, Busch offers the largest selection of industrial vacuum and pressure technology available today to meet their customer’s operating and cost saving goals. Contact us today!

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

Gast Manufacturing specializes in rotary vane, oilless, miniature, high-volume and dry vacuum pump products. We provide efficient, reliable vacuum pumps for a variety of applications. Our commitment to quality products, great service and environmentally friendly practices is unparralled.

At KNF Neuberger Inc., we specialize in providing high-performance vacuum pumps tailored to meet the demanding needs of diverse industries. Our vacuum pumps are designed with precision and reliability, offering optimal solutions for applications ranging from laboratory and medical environments to industrial and processing fields.

At Vacuubrand, we specialize in providing advanced vacuum technology solutions tailored for laboratory and industrial applications. We manufacture a comprehensive range of vacuum pumps, including oil-free diaphragm pumps, rotary vane pumps, and hybrid systems, all engineered for reliability, chemical resistance, and low maintenance.

Airtech is a leading manufacturer/supplier of various types of quality dry piston vacuum pressure pumps, rotary vane pumps (lubricated, dry), liquid ring vacuum pumps. We possess vast knowledge as a vacuum specialist. Serving medical, dental, food packaging and other industries. US warehousing.

At Welch Vacuum, we specialize in the design and manufacturing of high-quality vacuum pumps tailored to meet the diverse needs of industries worldwide. With a long history of innovation, we deliver reliable and efficient solutions for applications ranging from laboratory research to industrial processes.

More Laboratory Vacuum Pump Manufacturers

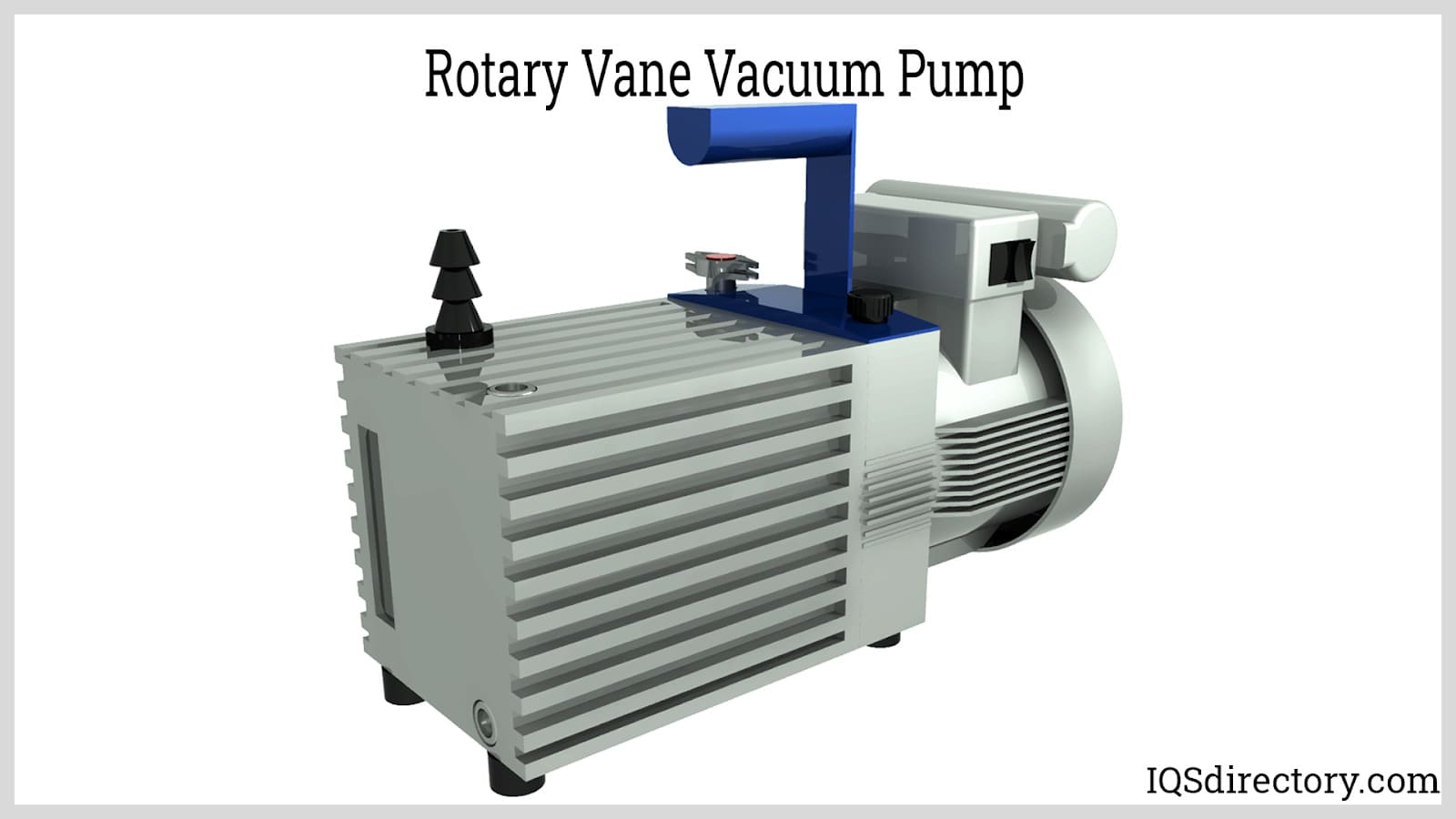

Scroll pump technology is also a dry technology, and can reach to 0.1 Torr, and in some cases as low as 0.001 Torr. Rotary vane vacuum pump technology and hybrid pumps (which combine rotary vane and diaphragm technology for fine vacuum with low maintenance) will reach as low as 0.001 Torr, while turbomolecular pumps can reach as low as 10-11 Torr, provided they are assisted by a “roughing pump.”

The roughing pump (often diaphragm or rotary vane) brings the pressures from atmospheric conditions to the range of 1 Torr or 0.1 Torr; the turbomolecular pump picks up from there to create the deeper vacuum.

Oil-free and particle free diaphragm pumps are usually preferred for those who need a roughing (sometimes called fore pump or backing pump) for small and middle sized turbomolecular pumps, because some diaphragm pumps can provide service intervals that match the very long service intervals of turbomolecular pumps.

An important principle is that the deepest vacuum is not the best vacuum for any application. The best scientific performance will be achieved by using a pump that produces vacuum in the most appropriate range for the application.

The level of vacuum needed for each of the applications noted earlier differs across a wide range. Many lab applications are accomplished in the “rough vacuum” range, down to about 1 Torr or 29.98 in. Hg. (gauge). Processes that operate in this range include filtration, aspiration, rotary evaporation, centrifugal concentration, gel drying, vacuum oven drying, and solid-phase extraction.

Such applications are best served with diaphragm pumps; the vacuum is in the right range and the operations are clean (no oil is needed), low maintenance, and can be made very chemical resistant, if needed.

Vacuum in the range between the lower limits of “rough vacuum” and 0.001 Torr is called “fine vacuum.” Laboratory processes requiring a fine vacuum include freeze drying, Schlenk lines, and residual drying. As noted earlier, this vacuum can be reached by rotary vane, hybrid and some scroll pumps. The correct choice will depend on the sensitivities of the application to oil, for example, or to dust that may be generated by the dry seal in a scroll pump.

Vacuum pumps are often integrated into other instruments and equipment as OEM (original equipment manufacturer) components. Such applications include gas sampling (e.g., for environmental testing or process monitoring), laser etching equipment in semiconductor manufacture, and test chamber evacuation in analytical instruments to ensure accurate results. They are used to evacuate test chambers and eliminate the influence of environmental conditions.

It is essential to consider your application requirements in order to choose the vacuum technology that is best suited to your laboratory and process needs. Start by defining the process for which vacuum will be used. Then define the level of vacuum and pumping speed needed. Finally consider chemical resistance, control requirements, maintenance intervals and environmental concerns (e.g., energy use, waste vapor capture) to determine the right pump.

These considerations will help narrow down which pumps will accommodate your applications and achieve the lowest lifetime cost of ownership. Then talk with your preferred vendor to avoid a mistake that can compromise your samples or process, or leave you with too much or too little capacity from your pump.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services