A liquid-ring pump with a liquid ring that seals when subjected to centrifugal force is a spinning positive-displacement gas pump. They can be used as gas compressors in addition to their usual application as vacuum pumps. In a liquid-ring pump, a spinning ring of liquid is stirred to create the compression-chamber seal, whereas, in a rotary vane pump, the vanes are an integral part of the rotor. The rotor is the only moving component, making them, by nature, low-friction designs. The shaft seals are the only points of sliding friction. An induction motor is primarily used to power liquid-ring pumps. Read More…

Busch Vacuum Solutions is a leading manufacturer of vacuum pumps, blowers, compressors, and customized systems using vacuum technology. With over 60 years of experience, Busch offers the largest selection of industrial vacuum and pressure technology available today to meet their customer’s operating and cost saving goals. Contact us today!

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

Gast Manufacturing specializes in rotary vane, oilless, miniature, high-volume and dry vacuum pump products. We provide efficient, reliable vacuum pumps for a variety of applications. Our commitment to quality products, great service and environmentally friendly practices is unparralled.

At KNF Neuberger Inc., we specialize in providing high-performance vacuum pumps tailored to meet the demanding needs of diverse industries. Our vacuum pumps are designed with precision and reliability, offering optimal solutions for applications ranging from laboratory and medical environments to industrial and processing fields.

At Vacuubrand, we specialize in providing advanced vacuum technology solutions tailored for laboratory and industrial applications. We manufacture a comprehensive range of vacuum pumps, including oil-free diaphragm pumps, rotary vane pumps, and hybrid systems, all engineered for reliability, chemical resistance, and low maintenance.

Airtech is a leading manufacturer/supplier of various types of quality dry piston vacuum pressure pumps, rotary vane pumps (lubricated, dry), liquid ring vacuum pumps. We possess vast knowledge as a vacuum specialist. Serving medical, dental, food packaging and other industries. US warehousing.

At Welch Vacuum, we specialize in the design and manufacturing of high-quality vacuum pumps tailored to meet the diverse needs of industries worldwide. With a long history of innovation, we deliver reliable and efficient solutions for applications ranging from laboratory research to industrial processes.

More Liquid Ring Vacuum Pump Manufacturers

How a Liquid Ring Vacuum Operates

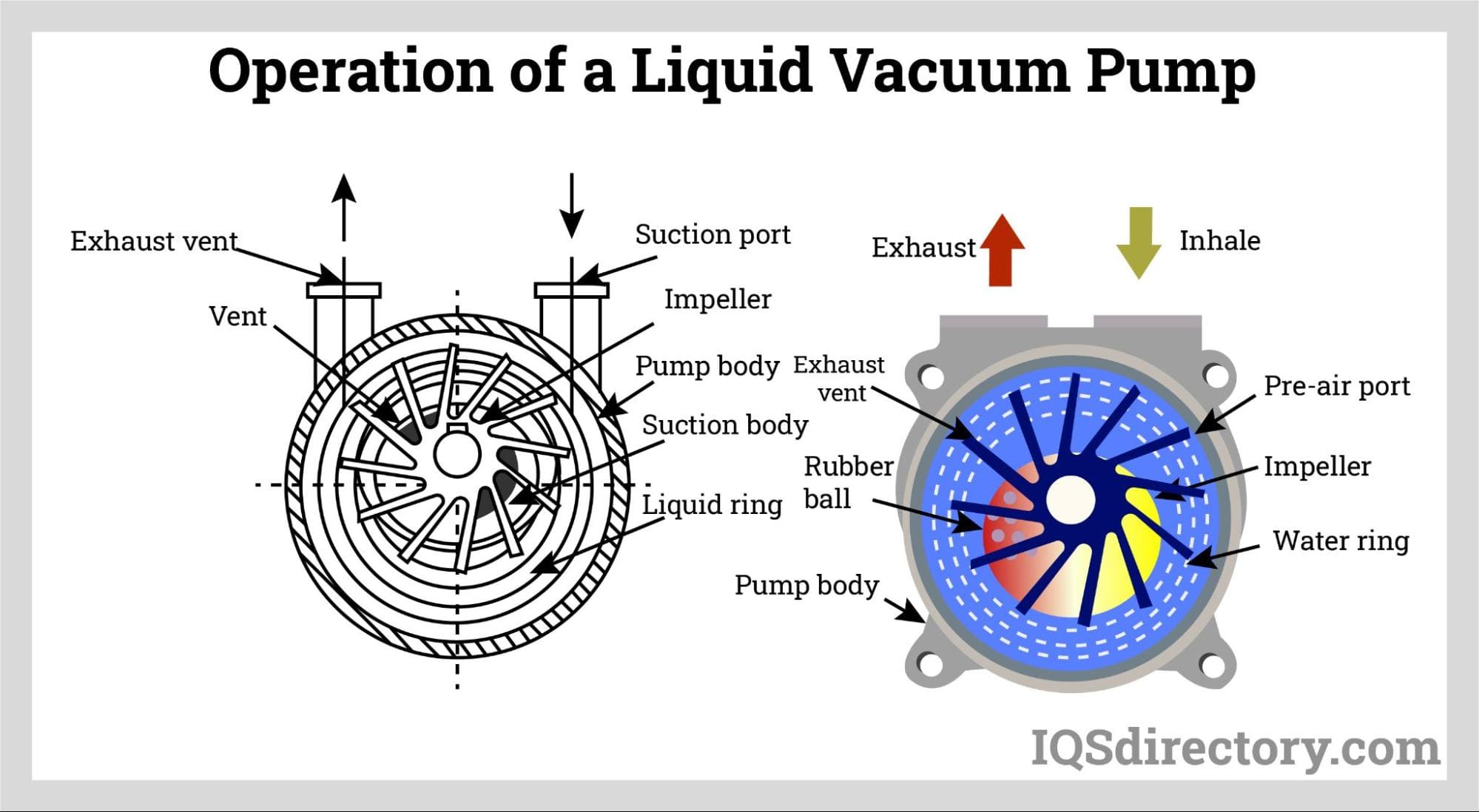

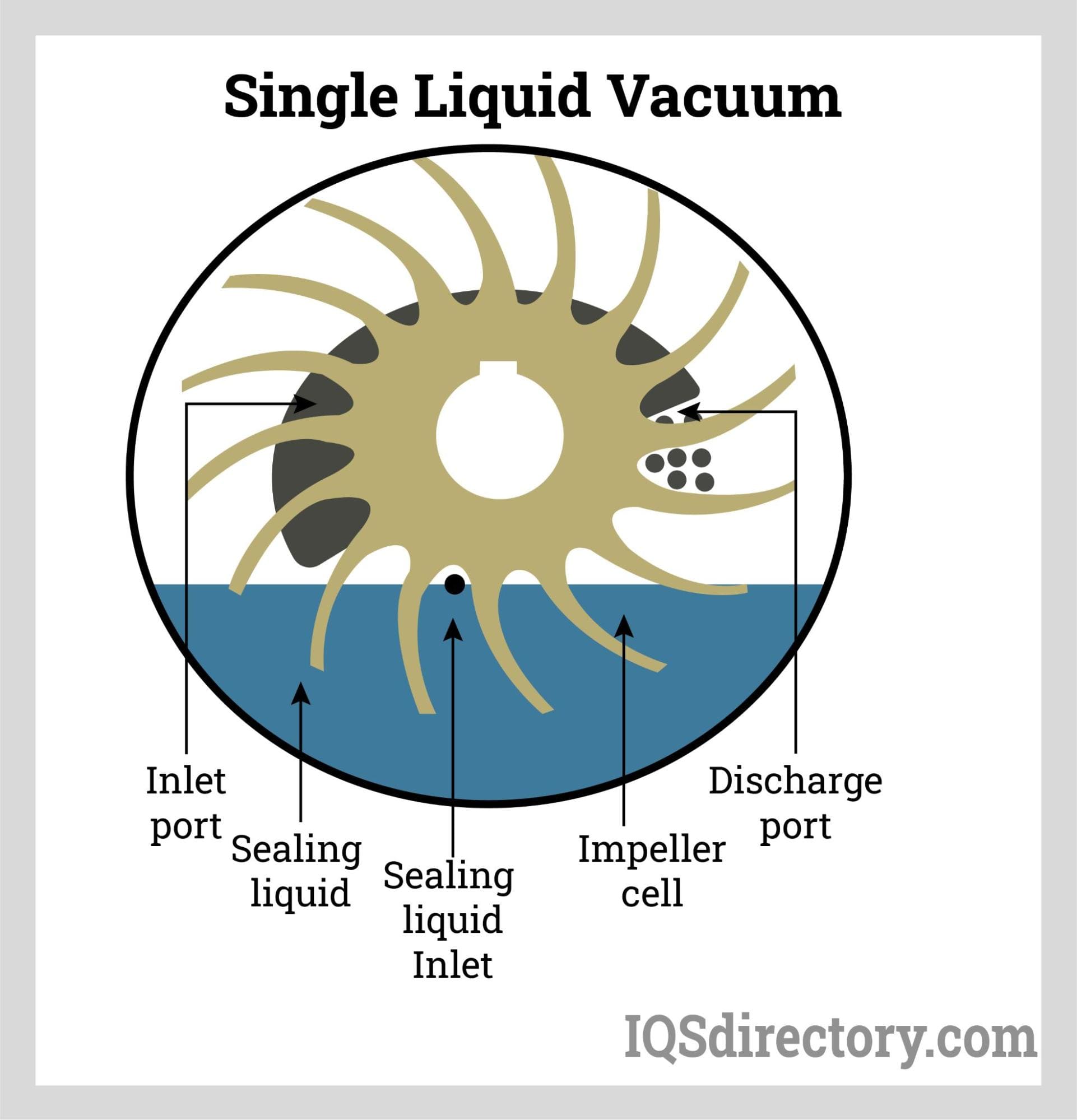

By rotating a vaned impeller that is eccentrically positioned within a cylindrical housing, the liquid-ring pump compresses the gas. When liquid (often water) is delivered into the pump, centrifugal acceleration causes the liquid to move cylindrically against the pumps inside the casing. The compression chambers are formed by seals produced by the liquid ring in the area between the impeller vanes.

Through an inlet port at the end of the casing, gas—often air—is sucked into the pump. The impeller vanes and the liquid ring create compression chambers that trap the gas. The gas is compressed due to the impeller's rotation, which reports to the discharge port at the end of the casing. A small amount of working liquid is discharged with compressed gas at the pump and is typically removed in a vapor-liquid separator.

Types of Liquid Ring Vacuum Pumps

There are single-stage and multistage liquid-ring systems. On a common shaft, a multistage pump typically has up to two compression stages. The ring-vapor liquid's pressure constrains the attainable pressure decrease in vacuum service. The rising volume of vapor produced from the ring liquid reduces the remaining vacuum capacity when the created vacuum approaches the ring-vapor liquid's pressure. As a result, the system's effectiveness decreases.

Suitable Liquids

Any liquid suitable for the process can be used as the sealant for liquid-ring vacuum pumps as long as it has the necessary vapor pressure characteristics. Although water is the most typical liquid sealant, any liquid can be utilized. Oil is the second most popular. Most oil-sealed liquid-ring vacuum pumps are air-cooled because oil has a very low vapor pressure.

Concentrated sulfuric acid is utilized for applications involving dry chlorine gas. The liquid ring vacuum pump is best suited for solvent (vapor) recovery since one may use it with any liquid. It is feasible to utilize toluene as the sealant if a process, such as distillation or a vacuum dryer, produces toluene vapors, providing the cooling water is cold enough to maintain the vapor pressure of the sealant liquid low enough to pull the appropriate vacuum.

Rerouting of the Ring-Liquid

The discharge stream also contains some ring liquid. Other apparatus not connected to the pump separates this liquid from the gas stream. Some systems use a heat exchanger or cooling tower to chill the discharged ring liquid before returning it to the pump casing. Depending on the system's architecture, pollutants from the gas may become trapped in the ring liquid in some recirculating systems.

These impurities concentrate as the liquid circulates, eventually harming the pump and shortening its lifespan. Filtration systems are necessary for this situation to make sure that pollution is kept at a manageable level. In non-recirculating systems, the hot liquid expelled (often water) is handled as waste. In this instance, the loss is made up for by new, refreshing water. Such "once-through" systems are becoming increasingly uncommon due to environmental factors.

Applications of Liquid Ring Vacuum Pumps

There are numerous industrial uses for these straightforward yet incredibly dependable pumps. On big steam-turbine generator sets, where vacuum levels are normally 30 to 50 mbar, they are employed to maintain condenser vacuums by eliminating incondensable vapors. On paper machines, they are employed to dewater the pulp slurry and remove water from press felts.

Another use is the vacuum forming of molded paper-pulp products (such as packaging and egg cartons). Other uses include soil remediation, where contaminated groundwater is vacuum-extracted from wells. Vacuum distillation also uses liquid-ring vacuum pumps to create a vacuum during refining of petroleum. In vapor recovery systems, liquid-ring compressors are frequently employed.

Liquid Ring Vacuum Pumps' Characteristics

Accepts Carryover: The pump is unaffected by soft solids, moisture, slugs, chemicals, and more. The pump discharge will merely remove these contaminants.

Cool and Quiet Operation: The pump operates quietly and cooly because the sealing water always moves inside the pump. The operation doesn't go above 85 dBA; therefore, it's fairly quiet.

Constant Operation at any Vacuum Level: The pump can operate continuously at any vacuum level, from 29 in. Hg to atmospheric pressure. Liquid ring vacuum pumps are built solidly and created for a long service life of continuous operation. This results in easier maintenance and longer pump life. The user benefits from less wear and easier, more inexpensive maintenance.

Environmental Benefits: Pumps do not need to have their oil, filters, oil pans, condensers, or other parts replaced. Because of this, plant rooms operate smoothly, free of oil pollution and oil discharges into sewage systems.

Benefits of Liquid Ring Vacuum Pumps

- Unlike most other vacuum pumps, it has a simpler design and uses a rotation system.

- Any casting metal may be used to make it.

- Small vibrations and sounds

- The temperature of the discharged gas barely increases.

- M3/hr suction capacities range from 20 to 54,000.

- Lowering the operating pressure to 33 mara

- Dry and wet gases

- High tolerance for spilled liquids

- Minimal water use

- Low levels of noise

What to Consider when Choosing Liquid Vacuum Pumps

It's crucial to consider aspects like the manufacturers that produce the liquid vacuum pumps, the necessary vacuum level, and the total cost of the pump when choosing a liquid ring vacuum pump. In addition, getting a pump from a recognized supplier with a track record of excellence and dependability is crucial.

Choosing the Proper Liquid Ring Vacuum Pump Manufacturer

To make sure you have the most positive outcome when purchasing a liquid ring vacuum pump from a liquid ring vacuum pump manufacturer, it is important to compare at least 4 to 5 companies using our list of liquid ring vacuum pump manufacturers. Each liquid ring vacuum pump manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each liquid ring vacuum pump business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple liquid ring vacuum pump businesses with the same message.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services