Most vacuum pump hardware is made from stainless steel or aluminum because of those materials’ strength and gas non-permeability. Read More…

Busch Vacuum Solutions is a leading manufacturer of vacuum pumps, blowers, compressors, and customized systems using vacuum technology. With over 60 years of experience, Busch offers the largest selection of industrial vacuum and pressure technology available today to meet their customer’s operating and cost saving goals. Contact us today!

Founded in 1885, Becker is still family owned and a leader in innovation. From their innovative products & designs to their team of loyal, experienced & talented employees, you will find the solutions you are looking for at Becker. Becker’s vacuum pumps are of the highest quality and you are guaranteed to go home satisfied and continue to be satisfied in the many years to come.

Gast Manufacturing specializes in rotary vane, oilless, miniature, high-volume and dry vacuum pump products. We provide efficient, reliable vacuum pumps for a variety of applications. Our commitment to quality products, great service and environmentally friendly practices is unparralled.

At KNF Neuberger Inc., we specialize in providing high-performance vacuum pumps tailored to meet the demanding needs of diverse industries. Our vacuum pumps are designed with precision and reliability, offering optimal solutions for applications ranging from laboratory and medical environments to industrial and processing fields.

At Vacuubrand, we specialize in providing advanced vacuum technology solutions tailored for laboratory and industrial applications. We manufacture a comprehensive range of vacuum pumps, including oil-free diaphragm pumps, rotary vane pumps, and hybrid systems, all engineered for reliability, chemical resistance, and low maintenance.

Airtech is a leading manufacturer/supplier of various types of quality dry piston vacuum pressure pumps, rotary vane pumps (lubricated, dry), liquid ring vacuum pumps. We possess vast knowledge as a vacuum specialist. Serving medical, dental, food packaging and other industries. US warehousing.

At Welch Vacuum, we specialize in the design and manufacturing of high-quality vacuum pumps tailored to meet the diverse needs of industries worldwide. With a long history of innovation, we deliver reliable and efficient solutions for applications ranging from laboratory research to industrial processes.

More Vacuum Pump System Manufacturers

A perfect vacuum is a space in which no matter is present. No perfect vacuum exists in reality, and no machinery can create one. But industrial vacuum pumps can achieve varying degrees of artificial evacuation for uses in many industries and applications.

Low vacuums, which are partial vacuums with relatively high levels of residual atmosphere, can be created by small vacuum pumps for light industrial tasks. Many light bulbs, for example, must be partially evacuated or filled with an inert gas in order to function.

For many other applications, though, higher degrees of evacuation are necessary. In laboratory applications, high-tech electronics fabrication and some contexts in the healthcare industry, vacuums with very low levels of atmospheric pressure can be necessary. High and ultra high vacuums are necessary for creating these kinds of vacuums, and in some cases, a series of vacuum pumps may be connected to the same inlet line.

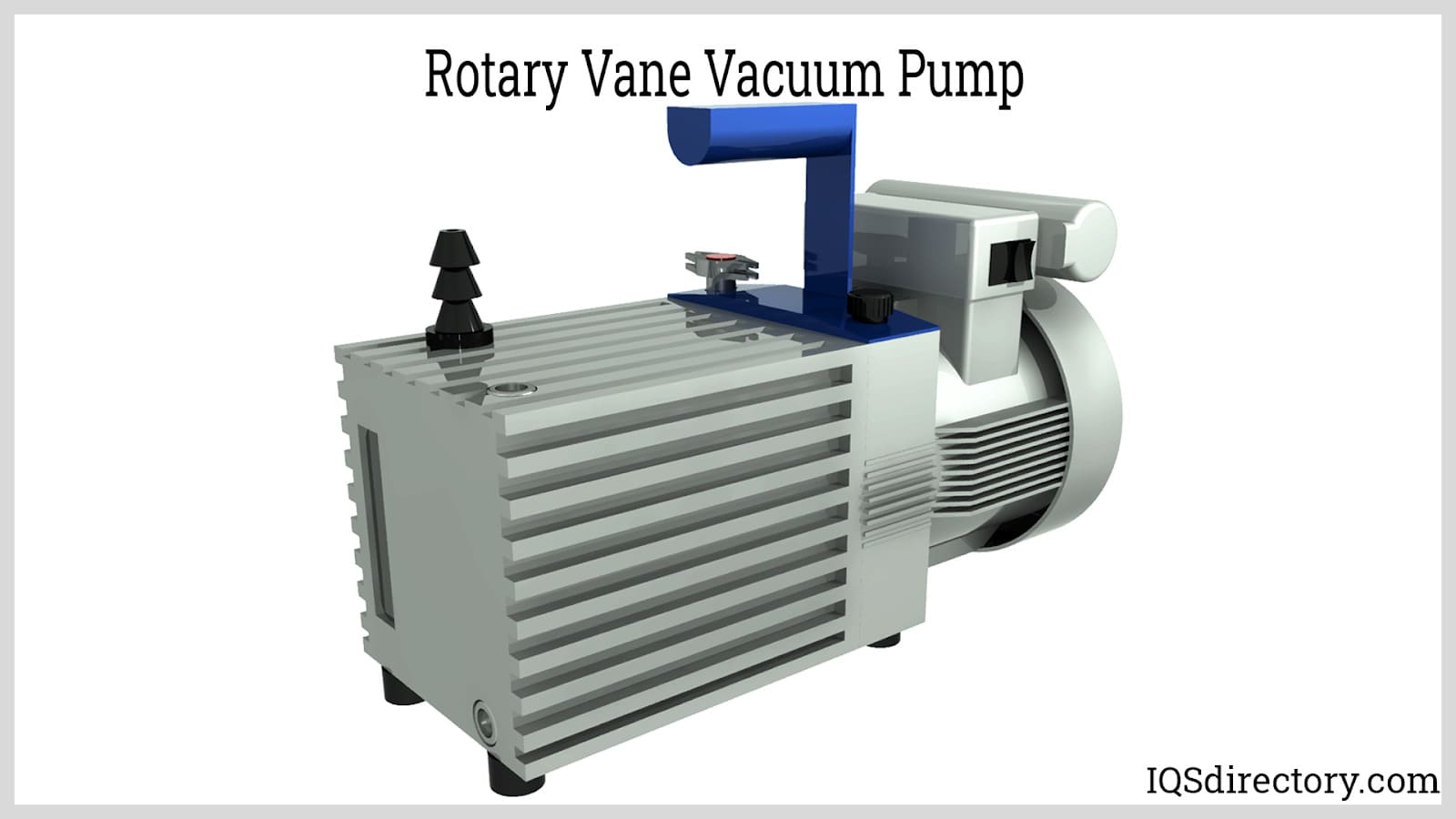

There are three main categories of vacuum pumps: positive displacement, momentum transfer and entrapment pumps.

Positive displacement pumps expand one part of a vacuum chamber while collapsing another; this compresses the gas inside and causes it to be evacuated. Momentum transfer pumps facilitate repeated collisions between gas molecules and rotors or steam jets that impart momentum and direct the molecules out of the chamber.

Entrapment pumps use condensation created by rapid heating and cooling to compress and trap gas molecules in a solid or absorbed state. Each pump variety can be used in conjunction with another to create vacuums of varying pressure levels. For example, a positive displacement pump, an absorption pump and a momentum transfer pump could be used to bring pressure down from 760 Torr to as low as 10 Torr (1 Torr is equal to the fluid pressure exerted by 1 mm of mercury at sea level).

Within those three vacuum pump categories, all vacuum pumps can be categorized as either wet or dry. If the vacuum uses oil for lubrication or a ring of liquid sealant, that system is considered to be a wet system. Dry vacuum pumps are systems that make no use of any liquids at any time.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services